What happens to the battery?

Safe servicing, storage and disposal

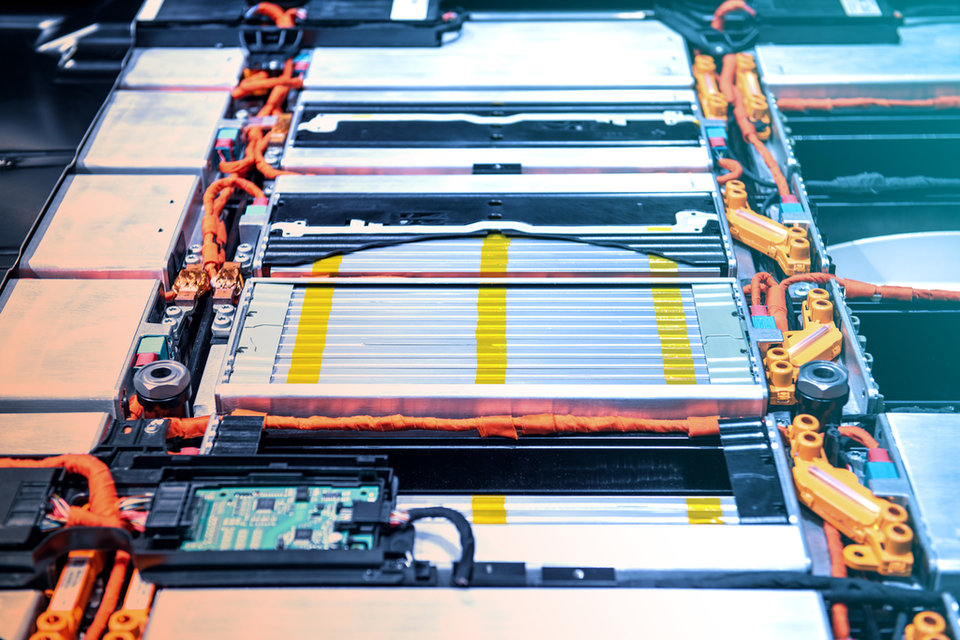

Decarbonising battery production

While battery powered vehicles offer a clear route to low and zero emission motoring, there remains a challenge to overcome in the production of the vehicle. As it stands, making an EV can generate around +80% more CO2 emissions than an equivalent ICE car. In large part, this is due to the raw materials in the battery and increased metals content in the vehicles. It may take more than 20,000 miles driven before the GHG emissions from producing and driving an EV are comparable with an ICE vehicle.

Factors like metal extraction techniques and recycling will play a part in bringing this down, as well as access to clean energy. For example, over time, it will be possible to introduce more recycled rather than virgin materials into the production chain. However, at the moment, supply of recycled content which is suitable for automotive production is challenged. There is also a pathway to decarbonising the raw materials production methods, for example the introduction of hydroelectricity into the aluminium smelting and steel processing activities.

Philip Nothard, Insight and Strategy Director, Cox Automotive: “Increased renewables in the electricity grids worldwide will support decarbonising the automotive manufacturing sector. However, the investment required to transform global automotive manufacturing into a low or zero emission industry is significant. As some countries push forward, others are lagging behind. This could cause a shift in where vehicle manufacturers choose to locate future plants.”

The Cox Automotive vision for electric vehicles

We believe battery-powered vehicles will be the dominant form of transportation in the future for people and goods. We are strategically steering our business to support the global transition to battery power and, ultimately, continue to be one of the top automotive services providers in the world.

We believe EVs are an important part of reducing greenhouse gas emissions and meeting the goals on climate change. Cox is committed to driving positive environmental change though our efforts to achieve carbon and water neutrality by 2034 and achieve zero waste to landfill by 2024.

We believe in a closed loop ecosystem for EV batteries to reduce the environmental impact of metals mining. We support practices that enable the extension of EV battery first lives and end of life reuse and recovery treatments.

To support the above, Cox Automotive Mobility acquired EV battery provider Spiers New Technologies (SNT). The acquisition will allow Cox Automotive to have greater control over the lifecycle of its EV vehicles and their individual parts.

Battery servicing, repair and maintenance

During a discussion in the UK House of Lords in early 2020, concern was raised about the potential hazard electric vehicles could cause if they breakdown on the smart motorway network. Many manufacturers advise against towing the vehicles because the car’s motor is always mechanically connected to the wheels and there is no true ‘neutral’ gear. This potentially adds time and complexity, as vehicles need to be recovered on a low loader.

Several breakdown providers are now exploring options to ensure vehicles and their occupants can quickly reach a place of safety in case of any issues. These include onboard emergency charging facilities and the All-Wheels-Up recovery system in some patrol vans for the RAC, as well as the new free-wheeling hub technology and Multi-Fit wheel from the AA.

Some manufacturers are also looking to support EV drivers through Vehicle to Load technology (V2L) which allows one EV to donate charge to another. While this may not be fully appropriate at the roadside, due to slow charging times, it could prove of benefit in fixed locations such as car parks and campsites. US manufacturer Rivian is also working on an emergency tow-charging mode, using regenerative braking technology to refill the battery while the vehicle is being towed.

Roadside support for EVs

“All our patrols are equipped with unique free-wheeling hub technology that helps us to rescue EV drivers quickly and safely. It means fewer breakdown worries and shorter waiting times for drivers. Previously it was not possible to tow EVs, as many manufacturers recommended against it. The free-wheeling hub can be fixed to the rear wheels of stricken vehicles, using the AA’s Multi-Fit wheel, so that it turns independently from the car.

“All of our patrols are also trained in electric vehicles to IMI Level 1 equivalent, with many also completing the Level 2 standard. With all of this investment, it is important to recognise that EVs make up a very small, although rapidly growing, proportion of current workload at just over 1%. As the EV transition takes place, we will continue to support ICE vehicles as long as they are still running.”

Dean Hedger, EV New Business Development Manager, the AA

Batteries and the fire risk?

In August 2021, General Motors confirmed it will recall all Chevrolet Bolt electric vehicles sold worldwide since launch in 2017 to fix a battery problem that could cause fires. In the meantime, owners are being advised to park outdoors and not exceed 90% charge on the battery. Ford, BMW, Volvo, and Hyundai have also issued battery recalls in recent months, while Tesla is dealing with several court cases in the US and Norway around battery health and over-the-air updates.

Vehicle fires happen in ICE vehicles, albeit rarely. However, battery cells in EVs can be particularly sensitive to heat and sparks, causing potentially higher risk of damage to the vehicle and the people around it. A Freedom of Information (FoI) request in the UK found the London Fire Brigade dealt with 54 electric vehicle fires in 2019, compared with 1,898 petrol and diesel fires. This suggests an incident rate of 0.04% for ICE car fires and more than double that for plug-in vehicles at 0.1%.

The challenge of EV fires

Peter Wilkinson, Technical Director at the Institution of Fire Engineers (IFE):

“Lithium-ion batteries are a popular technology for electric vehicles because they store a huge amount of energy in a very small space. However, if the battery is exposed to excessive heat, or there is a penetration in the battery case, then an internal short circuit causes heat that triggers a chemical reaction and a process called thermal runway, which can lead to ignition, or in some cases even explosion.

“Although these fires remain rare, when they do occur, they can be extremely dangerous. During an electric vehicle fire, over 100 organic chemicals are generated, including some incredibly toxic gases such as Carbon Monoxide and Hydrogen Cyanide – both of which are fatal to humans.

“Once the fire has been extinguished, the problem remains that electric vehicle fires can reignite hours, days or even weeks after the initial event, and they can do so many times, making disposal and storage of a fire-damaged vehicle a challenge.”

Electric vehicle storage and transport

As more electric vehicles enter the second hand and resale markets, it is important they are transported and stored correctly between drivers. Some manufacturers recommend leaving them plugged in while not in use; others have a ‘deep sleep’ mode when not in operation. In either case, it is beneficial to keep them at 10% to 80% charge, if at all possible, to maintain the high voltage battery health.

There are also differences in the 12-volt battery, with options to either disconnect it while the vehicle is in storage or attach it to a trickle charger. Much of this depends whether the vehicle will be out of operation for more than 30-days. Energy-draining features which might need to be turned off include automatic map updates, temperature controls, and predictive battery reconditioning.

As with any vehicle, tyres will need to be rotated to prevent flat spots. Alternatively, the vehicle can be driven every few weeks or raised off the ground so there is no pressure on the tyres. The advice is to keep vehicles in a weatherproof location; however, some commentators suggest caution should be exercised if there are hundreds of electric vehicles being stored in the same enclosed environment.

Battery-as-a-Service (BaaS)

While most passenger and commercial vehicles will spend more than 15 years on the roads through various owners, the majority of batteries at the moment have an estimated lifetime of around five to eight years (or 100,000 miles). Manufacturers are extending battery warranties and in many cases they are double that of the mechanical warranty. Battery-as-a-Service (BaaS) seeks to address this through a leasing model which offers pricing per kWh, per km driven, or on a monthly basis. This is an emerging market and there is limited evidence to date as to how successful and profitable this will be for providers and operators.

For consumers, a lack of knowledge and transparency around battery health is influencing anxiety around how to ensure you are getting a good deal if you buy a used EV. The market is still forming for values in second and third life, and this further complicates financing of vehicles and decisions about how the replacement battery market will operate.

Replacement batteries in the UK market could cost anything from £5,000 used or refurbished to £15,000 new, which is a significant investment for a driver who picked up their second-hand EV at a comparatively low price. It is possible to replace single cells rather than the whole battery, which could bring the prices down to the hundreds rather than thousands of pounds.

Battery degradation

One study by Which? in the UK found an -8% reduction in usable range over six years due to battery degradation, which may not be an issue for buyers of new vehicles but will perhaps have an impact on the used market. Indeed, a Cox Automotive consumer study in the US found four in five (83%) consumers are sceptical about used EV batteries.

Battery degradation can be accelerated by extremes of temperature, particularly warmer climates, as well as the regular use of fast charging networks which tend to cause the battery to run hotter during the charging process. If vehicles often go through a 0 to 100% charge cycle, this can also speed up battery depletion. However, such intensive charge cycles are unlikely in most EV use case scenarios, with EV drivers recommended to keep their battery charge between 20% and 80%.

Recyclers, transporters, and services will require access to a standard set of data to effectively repurpose end of first life batteries. Cox Automotive is supporting calls for a standard battery health score (state of health / SoH) to enable smart end-of-life decisions and vehicle valuations. This aligns with the recent acquisition of Spiers New Technologies, which offers ALFRED; a PHP / MySQL web application that collects, manages, and processes battery and battery related information.

A new life for batteries

By 2030, Cox Automotive estimates 100 GWh of battery capacity worldwide will be retired annually from electric vehicles, from nearly 2,000 GWh of capacity demand. Just 1 GWh could power around 725,000 homes, suggesting significant opportunity for second and third life batteries in a decentralised and distributed energy sector. Greenpeace East Asia believes lithium-ion batteries decommissioned from EVs and repurposed for energy needs could meet the world’s needs by 2030; suggesting repurposed batteries could support China’s 5G telecoms infrastructure and data centres as a start point.

While some end-of-life options currently include export and disposal through landfill, the direction of travel is towards reuse and recycling. Both options are potentially challenging at the moment, but significant investment is taking place. Greenpeace East Asia suggests repurposing batteries could save 63m tonnes of carbon emissions from new battery manufacturing. The incentive to develop new streams for EV batteries once their in-car life is finished is significant. Repurposing is likely to be more effective than disassembling batteries and extracting materials.

In September 2021, Cox Automotive acquired Spiers New Technologies (SNT), a business that provides repair, remanufacturing, refurbishing, and repurposing services for battery packs. This follows collaboration between the two businesses which saw a battery health diagnostic tool built using Spiers’ software platform, ALFRED. Spiers is one of a few companies that specialises in giving EV batteries a ‘second life’ after they are no longer fit for use in a vehicle. Around 80% to 90% of the batteries SNT receives are from manufacturers, with the rest from auto dismantlers.